EPISODE 3, WE SPENT TIME TOGETHER FOR 12 HOURS

6/10/2010

Wednesday

10 A.M

10.30am – Mr Shaman shows us how to inoculate inoculums and sampling procedure. The sample is taken for every 2 hours and started at time t=0. Then, the OD (optical density) is measured by using the spectrophotometer at 600nm. The glucose level is also being measured from every sample taken by using the glucose detector.

Before inoculation

- Setup the agitator speed at 700 rpm

- To remove oxygen level in medium. We inject the nitrogen gas in bioreactor. After we inject the nitrogen gas, we calibrate the fermentor at 0 %.0 % indicate that no oxygen in the medium. After that we add the oxygen until 100 %. We do the second calibration at this point.100% indicate 100% dissolved oxygen in the medium

Procedure during inoculation

1- Wear the gloves and sterilize your hand with 70% of ethanol solution.

2- Spray at the inoculation inlet tube and also at the end of the inoculation flask . Open the clamp of the inoculation flask. Take off the silicone tube at the inoculation inlet and immediately transfer the inoculums into the bioreactor. This is done to avoid any contaminations.

3- The inoculation performed by gravity feeding ( holding the inoculums vessel higher than the fermentor)

4- The inoculation inlet must be closed quickly after the inoculums transfer process.

Then our bioreactor is ready to use!!!!!

Sampling procedure

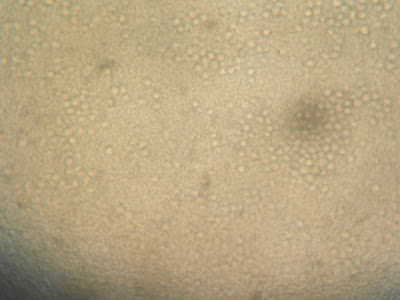

This procedure is important as it is used to know whether the yeast containing inside the media is still alive or dead. But, be careful during this procedure as it can lead to contamination if doing it wrongly. So, here’s the procedure.

1- A syringe is used to suck out the sample from the bioreactor and it should be connected to a filter so that the inlet air would be filtered. A Y connector is used to connect the sample bottle to the bioreactor and the sample tube to suck the sample out.

2- The clamp connecting to the bioreactor must be opened first. Then, the sample is suck out by using the syringe. Sample is collected in the sampling bottle. The clamp is closed again.

3- After that, the clamp connecting to the end of the tube is opened to take out the sample for OD measurement. By using the syringe again, the sample in the sampling bottle should be suck out ALL OF THEM!! (this is because to avoid the inaccuracy during the OD measurement)

4- Then, after taking the sample. Spray the alcohol at the end of silicone tube immediately

5- Wrapped the silicone tube with cotton and aluminium foil to prevent contamination

6- All the activities were recorded by Iris Software. From our experiment, Iris will give us information on the operation of our bioreactor. The parameters we selected were dissolved oxygen, agitator speed, anti foam, base, temperature and pH.